Home » testing

EMCC Stator Coils

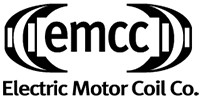

Form Wound Stator Coils/Windings

The Electric Motor Coil Company is dedicated to becoming a form coil supplier of choice. With the use of leading-edge automation and technological advancements, EMCC is striving to serve its customers to the highest level. Time is valuable and customers depend on quick solutions. You need a supplier you can depend on too, which is why we have same-day quoting, usually within a few hours.

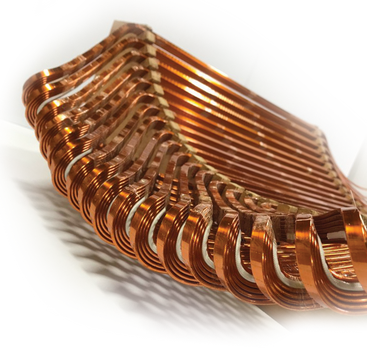

- Magnet Wire Meets All ANSI/NEMA MW Standards

- VPI Dip or Bake

- Stator Coils up to 6900 VAC

- Rotor Bars and Wound Rotors

- Class F Varnish Treated Insulation Systems

- Class H Insulation Systems

- Stator Traction Coils Available

Why Choose EMCC

Comprehensive Stator Coil Solutions

Innovation

State-of-the-art Coil Manufacturing

EMCC boasts the most advanced manufacturing facilities and testing equipment. We are constantly innovating to streamline productivity, adopt technological advances, eliminate waste, and pursue lower costing to meet evolving customer needs.

The Electric Motor Coil Company has multiple automated coil manufacturing machines, such as Cut and Strip Lines, CNC 6-Axis Tapers, Flat Coil Tapers, Turn Tapers, CNC Component Shearing, Stamping, Coil Forming, and Automated Q/C Inspections.

Quality Assurance

We are a Best-In-Class Coil Manufacturing Company.

EMCC is dedicated to operational excellence, we are relentless in the never ending pursuit of finding ways to improve quality, performance, and cost.

To ensure the highest quality, each coil undergoes a strict quality control process from pre-production to final shipping.

Equipped with the latest instrumentation, tools, and sophisticated test equipment, our Q.C./Q.A. department is capable of accurately sampling, inspecting, and testing components to verify they conform to OEM defined specifications.

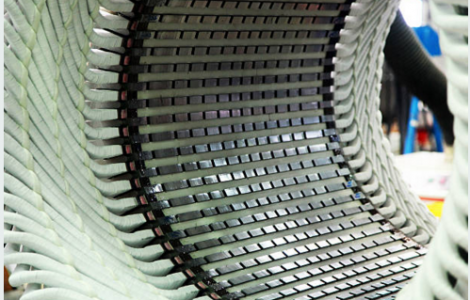

Coil Insulation Systems

- Class F Varnish Treated Coil System

- Vacuum Pressure Impregnation

- Class H Insulation Systems

Crease-Free Taping

Automated crease free taping for consistent insulation overlap integrity and perfectly fitting coils.

EMCC Automation

EMCC has multiple automated coil machines such as cut and strip lines, CNC 6-axis tapers, flat coil tapers, turn tapers, CNC component shearing, stamping, coil forming, and inspections.

Perfectly Fitting Coils

Each Coil set that we manufacture is first developed using Computer-Aided Design, to ensure your coils fit perfectly, every time, whether you need one set or 100 sets.

IN-HOUSE MACHINE SHOP

EMCC has CNC mills, CNC lathes, plasma cutters, welders, and skilled machinists that allow us to build coil tooling that many other suppliers simply cannot replicate.

Coil Testing – Proven Reliability

EMCC exposes all products to rigorous and extensive testing above and beyond industry standards, resulting in the highest quality product delivered and complete customer satisfaction. Every Coil is 100% tested.

Coil Management Services

At EMCC, we offer our clients custom-tailored life-cycle management solutions. By working together, we help you plan and take action, limiting unplanned operational downtime.

24/7 Coil Manufacturing

When that call comes in – we are here to help at a moment’s notice. Costs associated with unplanned downtime can be immense. For this reason, The Electric Motor Coil Company offers 24/7 Emergency Service to our valued clients. We are fully committed to getting you the quality motor and generator coils/windings you need -with the fastest emergency turn around times in the industry.